咨询服务热线: 0514-87885777

腾达试验仪器厂:

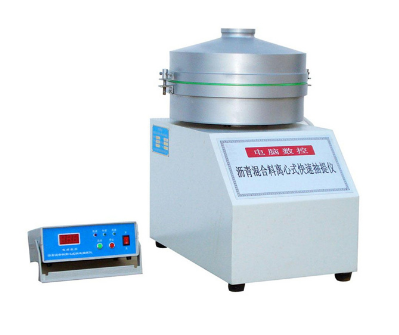

沥青离心式分离机适用于热拌热铺沥青混合料路面施工时的沥青用量检测,以评定拌和厂产品质量。此法也适用于旧路调查时检测沥青混合料的沥青用量,用此法抽提的沥青溶液可用于回收沥青,以评定沥青的老化性质。

Asphalt centrifugal extractor is suitable for testing the amount of asphalt used in the construction of hot-mixed hot-paved asphalt mixture pavement to evaluate the quality of the product of the mixing plant.This method is also suitable for detecting the amount of bitumen in asphalt mixtures when surveying old roads.The bitumen solution extracted by this method can be used to recover bitumen to evaluate the aging properties of bitumen.

沥青离心式分离机技术参数:

★料碗容量:1500g/3000g

★转速:3000r/min

★锅内径:280mm

★环境温度:≤35℃。

★相对湿度:≤85%。

★整机功耗:500W。

★仪器净重:60kg

★电源电压:220v

★外形尺寸:600X440X620mm

Technical parameters of asphalt centrifugal extractor:

★Bowl capacity:1500g/3000g

★Speed:3000r/min

★Inner diameter of the pot:280mm

★Ambient temperature:≤35℃.

★Relative humidity:≤85%.

★Whole machine power consumption:500W.

★Net weight of the instrument:60kg

★Power supply voltage:220v

★Dimensions:600X440X620mm

沥青离心式分离机操作规程:

★向装有试样的烧杯中注入三氯乙烯溶剂,将其浸没,记录熔剂用量,浸泡30min,用玻璃棒适当搅动混合料,使沥青充分溶解。注:也可直接在离心分离器中浸泡

★将混合料及溶液倒入离心分离器,用少量溶剂将烧杯及玻璃棒上的粘附物全部洗入分离器中。

★称取洁净的圆环形滤纸质量准确至0.01g。注意,滤纸不宜多次反复使用,有破损者不

★将滤纸垫在分离器边缘上,加盖紧固,在分离器出口处放上回收瓶,上口应注意密封,防止流出溶液成雾状上散失。

★接通电源,打开开关,三位数码显示000表示机器正常。按启动键,分离机开始工作,工作过程为低速20秒(这时从机器中部看到点击转动,如不转,可微调后面板低速调节,使之慢慢转动)中速20秒,(同低速相同,调节中速使之转速高于140秒,合计180后自动停机。

★从上盖得孔中加入新的熔剂,稍后3-5min后,按复零键再按启动键,分离机重新自动完成,如此操作数次直到流出的抽提液成清澈淡黄色为止。注意:每次加入三氯乙烯溶剂不得超过浸泡容量,一般200毫升左右。

★卸下上盖,取圆形环滤纸,在通风橱或室内空气中蒸发干燥后,然后放入105±5℃烘箱中干燥,称取质量,其增重部分为矿粉的一部分。

★将容器中的集料仔仔细取出,在通风橱或空气中蒸发后放入105±5℃烘干(一般需要4h),然后放入干燥中冷却至温室,称取集料。

Asphalt centrifugal extractor operating procedures:

★Inject the trichloroethylene solvent into the beaker containing the sample,immerse it,record the amount of flux,soak it for 30 minutes,and stir the mixture with a glass rod to fully dissolve the asphalt.Note:You can also soak directly in the centrifuge

★Pour the mixture and solution into the centrifugal separator,and wash all the adherends on the beaker and glass rod into the separator with a small amount of solvent.

★Weigh the clean round filter paper to an accuracy of 0.01g.Note that filter paper should not be used repeatedly.

★Place the filter paper on the edge of the separator,cover it tightly,and put a recovery bottle at the separator outlet.The upper mouth should be sealed to prevent the outflowing solution from becoming misty and lost.

★Turn on the power and turn on the switch.The three-digit digital display 000 indicates that the machine is normal.Press the start button,the separator starts to work,the working process is 20 seconds at low speed(at this time,click and rotate from the middle of the machine,if you do not turn,you can fine-tune the rear panel low speed adjustment to make it rotate slowly)at 20 seconds,Low speed is the same,adjust the medium speed to make the speed higher than 140 seconds,and stop automatically after a total of 180.

★Add new flux from the hole in the upper cover.After 3-5min later,press the reset button and then the start button.The separator will automatically complete again.Do this several times until the extracted liquid becomes clear yellow.Note:Each time you add trichloroethylene solvent,it should not exceed the soaking capacity,usually about 200 ml.

★Remove the upper cover,take the circular ring filter paper,evaporate and dry it in a fume hood or indoor air,then dry it in an oven of 105±5℃,weigh it,and the weight increase part is part of the mineral powder.

★Take out the aggregates in the container carefully,evaporate them in a fume hood or air,and put them in 105±5℃to dry(usually 4h),then put them in the cooler to the greenhouse,and weigh the aggregates.

沥青离心式分离机仪具与材料:

离心抽提仪:由试样容器及转速不小于3000r/min的离心分离器组成,分离器备有滤液出口。容器盖与容器之间用耐油的圆环形滤纸密封。滤液通过滤纸排出后从出口流出收入回收瓶中,仪器必须安放稳固并有排风装置。

圆环形滤纸。

回收瓶:容量1700mL以上。

压力过滤装置。

天平:感量不大于0.01g、1mg的天平各一台。

量筒:小分度1mL。

电烘箱:装有温度自动调节器。

三氯乙烯:工业用。

碳酸铵饱和溶液:供燃烧法测定滤纸中的矿粉含量用。

其它:小铲,金属盘,大烧杯等。

Asphalt centrifugal extraction instrument and materials:

Centrifugal extraction instrument:It consists of a sample container and a centrifugal separator with a rotation speed of not less than 3000r/min.The container lid and container are sealed with an oil-resistant circular filter paper.After the filtrate is discharged through the filter paper,it flows out of the outlet and is collected in a recovery bottle.The instrument must be stable and equipped with an exhaust device.

Circular filter paper.

Recovery bottle:more than 1700mL.

Pressure filtering device.

Balances:one each with a sensitivity of not more than 0.01g and 1mg.

Graduated cylinder:small graduation 1mL.

Electric oven:equipped with automatic temperature regulator.

Trichloroethylene:industrial use.

Saturated solution of ammonium carbonate:for combustion method to determine the content of mineral powder in filter paper.

Others:small shovel,metal plate,large beaker,etc.

微信扫一扫