咨询服务热线: 0514-87885777

腾达试验仪器厂;

一、产品简介:

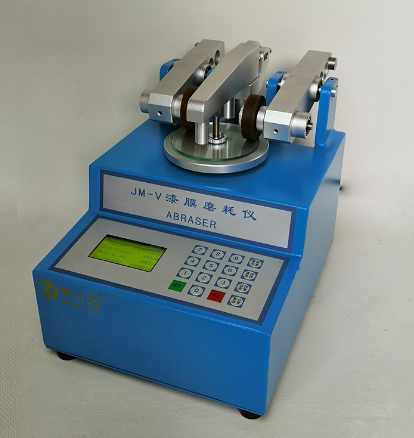

漆膜磨耗仪适用于GB/T15036.2、GB/T15102、GB/T18102、GB/T4893.8、ISO7784.2标准。对漆膜耐膜性能的测试和对木材饰面耐磨性能的测试必须采用同配置的转盘组件和磨耗轮,请在定货时予以说明(可选择“漆膜配置”、“木材配置”或“两用配置”)。转盘转速可在50-100r.P.m范围内按用户要求特殊设置(需订货时说明)

Product introduction:

Paint film abrasion tester is applicable to GB/T15036.2,GB/T15102,GB/T18102,GB/T4893.8,ISO7784.2 standards.The test of the film film resistance and the test of the wood surface abrasion resistance must use the same configuration of the turntable assembly and the wear wheel,please specify when ordering(select"film film configuration","wood configuration"or"Dual-use configuration").The rotating speed of the turntable can be set according to user requirements within the range of 50-100r.P.m(specify when ordering)

二、产品特点:

独有的磨耗工序将待测材料放在转盘上,两个磨耗轮以一定压力压在材料上使其受磨耗。磨耗轮随样件盘转动面转动,产生相对运动和磨耗,而转动(60 RPM或72 RPM)过程中磨耗轮轴相对于转盘转轴的偏移产生滑移运动,从而磨耗材料。面积为30平方厘米的样件承受磨耗时,样件表面材料受全角度颗粒或丝织状物磨损形成一完整的圆环。磨耗机是当前功能好的加速磨损试验仪。通过改变附件可以改变试验功能。这款耐用型仪器可以在一种物料同一点上进行重复测试,至厚约0.5"的材料破损或被磨掉。选择同的磨耗轮和附件可以模拟同的真实磨耗情况进行同的试验。

严格的控制保证可靠的结果精心挑选的磨耗轮磨料,质量高加在磨擦轮上的压力以克为单位磨耗轮稳定性经严格的质量控制电子测量转盘转动数真空吸尘器除磨屑。

Product Features:

Unique abrasion process Put the material to be tested on the turntable,and two abrasion wheels press the material with a certain pressure to wear it.The abrasion wheel rotates with the rotating surface of the sample disc to generate relative motion and wear.During the rotation(60 RPM or 72 RPM),the offset of the abrasion wheel shaft with respect to the rotation axis of the turntable generates a slip motion,thereby abrading the material.When the sample with an area of 30 cm2 is subjected to abrasion,the surface material of the sample is worn by full-angle particles or silk to form a complete ring.The abrasion machine is a current good accelerated wear tester.The test function can be changed by changing the attachment.This rugged instrument can be repeatedly tested at the same point of a material,and materials up to about 0.5"thick are damaged or worn away.The same wear wheel and accessories can be used to simulate the same real wear conditions and perform the same tests.

Strict control guarantees reliable results.Carefully selected abrasive wheel abrasives,high quality.Pressure on the friction wheel is measured in grams.Stability of the abrasive wheel is strictly controlled.Electronic measurement of the number of turntables.Vacuum cleaner to remove abrasive debris.

三、技术参数:

♦主电动机功率:40W

♦修磨电动机:JX5612 220V 90W 2800r/min

♦转盘转速:0~90r/min

♦橡胶砂轮:50*16*13

♦荷重砝码:250克500克750克

♦荷重砝码标示重量:500克750克1000克

砝码标示重量为施加压于试件表面的重力

荷重砝码上标示的重量=砝码实际重量+加压套重量250克(固定在仪器上)

例:荷重砝码上标示的重量为500克=砝码实际重量250克+加压套250克

♦砂轮平衡砝码:1克2克5克10克20克(销轴20克)

♦外形尺寸:主机:220*280*300(长*宽*高)

修磨机:300*205*175(长*宽*高)

♦重量:15Kg

Third,the technical parameters:

♦Main motor power:40W

♦Grinding motor:JX5612 220V 90W 2800r/min

♦Turntable speed:0~90r/min

♦Rubber grinding wheel:50*16*13

♦Load weight:250g,500g,750g

♦The indicated weight of the load weight:500g,750g,1000g

The weight indicates the weight applied to the surface of the test piece.

The weight marked on the load weight=the actual weight of the weight+the weight of the compression sleeve 250 grams(fixed on the instrument)

Example:The weight indicated on the load weight is 500 grams=the actual weight of the weight is 250 grams+the compression sleeve is 250 grams

♦Wheel balance weight:1g 2g 5g 10g 20g(pin 20g)

♦Dimensions:Host:220*280*300(length*width*height)

Grinding machine:300*205*175(length*width*height)

♦Weight:15Kg

四、工作原理:

严格的控制保证可靠的结果精心挑选的磨耗轮磨料,质量高加在磨擦轮上的压力以克为单位磨耗轮稳定性经严格的质量控制电子测量转盘转动数真空吸尘器除磨屑。

漆膜磨耗仪是由二个磨耗砂轮配置于转盘上,当转盘旋转时,左侧一个磨耗砂轮由外向样板表面**磨擦,而右侧一个磨耗砂轮由样板表面**向外磨擦。当转盘旋转一周时,在样板表面磨耗的痕迹是由互相重合,并呈X形相交的二园环组成。采用这种方式,其优点是使样板表面各个方向都受到磨擦,克服了一个方向往复运动的耐磨仪的缺点。

Fourth,the working principle:

Strict control guarantees reliable results.Carefully selected abrasive wheel abrasives,high quality.Pressure on the friction wheel is measured in grams.Stability of the abrasive wheel is strictly controlled.Electronic measurement of the number of turntables.Vacuum cleaner to remove abrasive debris.

The paint film abrasion meter is configured by two abrasion wheels on the turntable.When the turntable rotates,the left abrasion wheel is rubbed outward from the surface of the template,and the right abrasion wheel is rubbed outward by the surface of the template.When the turntable is rotated once,the wear marks on the surface of the template are composed of two circular rings that overlap each other and intersect in an X shape.In this way,the advantage is that the surface of the template is rubbed in all directions,which overcomes the shortcomings of the abrasion tester that reciprocates in one direction.

五、注意事项:

⑴测试结束后,应切断电源,清理仪器,将仪器罩好。

⑵长期用时,应将砂轮取下放好。

⑶一年至二年必须检修加油一次

Five;matters needing attention:

After the test,the power should be cut off,the instrument should be cleaned,and the instrument should be covered.

时For long-term use,the grinding wheel should be removed and placed.

⑶Must be overhauled once a year to two years

微信扫一扫