咨询服务热线: 0514-87885777

腾达试验仪器厂:

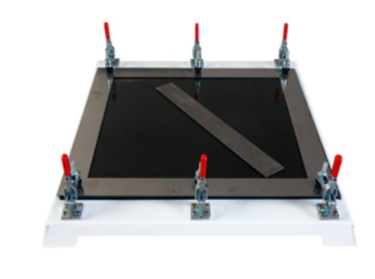

防水涂料涂膜模具符合GB/T16777-2008,GB/T19250-2003标准,本涂膜模框是建筑防水材料(聚氨酯类、聚丙烯酸酯类)拉伸性能系列试验,制备试样用的涂膜模具。用此涂膜模具能制出350mm320mm*1.5mm的试样膜,然后用切片机切割涂膜可制得符合GB/T528标准规定的哑铃状Ⅰ型试样,以备不同拉伸试验之用。

The coating film frame conforms to GB/T16777-2008 and GB/T19250-2003 standards.This coating film frame is a series of tests for tensile properties of building waterproofing materials(polyurethanes,polyacrylates),and a coating film mold for preparing samples..Using this coating film mold,a sample film of 350mm320mm*1.5mm can be made,and then the coating film can be cut with a microtome to obtain a dumbbell-shaped type I sample that meets the requirements of the GB/T528 standard for different tensile tests.

防水涂料涂膜模具技术参数:

★结构:本涂膜模具由模框、涂刮棒、基板及底座组成.

★尺寸规格:外框尺寸410mm*380mm*1.5mm

★内框尺寸350mm*320mm*1.5mm

★涂膜厚度(1.50.2)mm:

Coating film frame technical parameters:

★Structure:The coating film mold consists of a mold frame,a coating bar,a substrate and a base.

★Dimensions:410mm*380mm*1.5mm

★Inner frame size 350mm*320mm*1.5mm

★Coating film thickness(1.50.2)mm:

防水涂料涂膜模具使用方法:

★在试样制备前,所取样品及所用仪器均在标准条件下(温度23℃±2℃;相对湿度45%~70%)放置24h。

★为了便于脱模,在基板(玻璃板)上和模框上可用硅油或石蜡作脱模剂进行表面处理。

★在标准条件下,将静置后的样品搅拌均匀,若样品是双组分涂料,则按产品的配合比称取所需的主剂和固化剂,把两组分混合后充分搅拌5min。

★在不混入气泡的情况下将搅拌好的防水涂料立即倾倒于本涂膜模具中进行涂覆。

★样品应分次涂覆,A后一次用涂刮棒将其表面刮平,并在标准条件下养护168h。

★检查涂膜外观,表面应无明显气泡、光滑且平整。

★起膜后,用切片机切割涂膜,制得符合GB/T 528所规定的哑铃状Ⅰ型试样,以备不同拉伸试验之用。

How to use the coating mold frame:

★Before the preparation of the samples,the samples taken and the instruments used were placed under standard conditions(temperature 23°C±2°C;relative humidity 45%~70%)for 24 hours.

★In order to facilitate demolding,silicone oil or paraffin can be used as a mold release agent on the substrate(glass plate)and mold frame for surface treatment.

★Under standard conditions,stir the sample after standing evenly.If the sample is a two-component coating,weigh the required main agent and curing agent according to the product mix ratio,and mix the two components for 5 minutes.

★Pour the stirred waterproof paint into this coating film mold for coating immediately without mixing air bubbles.

★The sample should be coated in several steps.After A,the surface should be scraped flat with a coating bar and cured under standard conditions for 168h.

★Check the appearance of the coating film.The surface should be free of obvious bubbles,smooth and flat.

★After filming,use a microtome to cut the coating film to obtain dumbbell-shaped type I specimens that meet the requirements of GB/T 528 for different tensile tests.

微信扫一扫